The aim of our research is to create better modeling approaches that allow creating and understanding innovative, multifunctional structures under various conditions and loading. This is performed under the current research program titled “Intelligent and Green Marine Vessels”, which is supported by Seaspan Shipyards, NSERC, Vard Marine, Robert Allan and Serco. Several other companies and institutions are involved in some of our research areas.

Main focus areas are described below.

Structural Optimization and Generative Design

We are developing algorithms for sizing (parametric) and topology optimization of complex structures. These algorithms allow computers to create new structural forms which humans cannot devise, and to improve efficiency of existing designs. We are advancing a few aspects of optimization framework in order to handle large number of failure and production requirements, primarily for ships that need to comply with industry regulations.

Main research directions are:

- Constraint-handling approaches for swarm and evolutionary algorithms

- Topology optimization of complex structural parts that ensures structural integrity

- Surrogate models for structural optimization

For more information, please click here

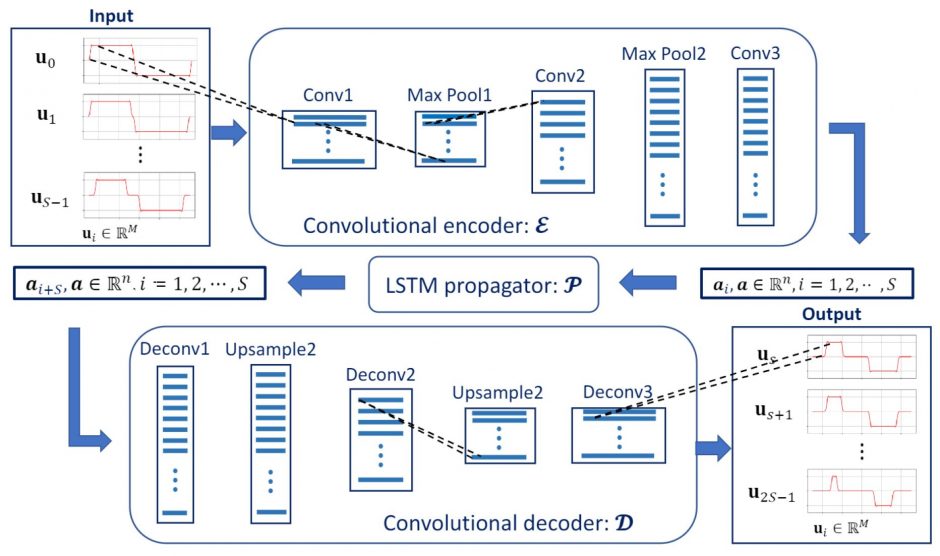

Deep Learning Models

We are working on several types of neural networks and other data-driven and physics-informed models as reduced-order models for analysis and optimization. The aim is to allow use of higher-fidelity models in early design of complex products where typically finite element analysis is computationally prohibitive. The applications span structural analysis, shape optimization and wave propagation.

For more information, please click here

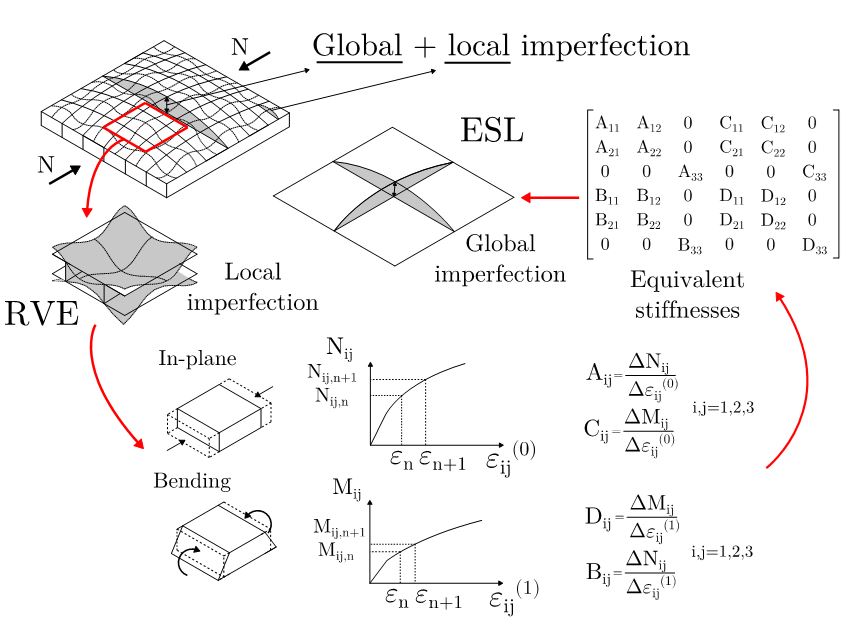

Mechanics of Functionally Graded Materials and Structures

We work on modeling vibrations and buckling of functionally graded structures (FGMs). Properties (and possibly materials) of these structures vary in different directions, combining desired features. We consider prismatic sandwich panels, functionally graded porous materials and stiffened panels. Beside mechanical loads, we are modeling the effects of thermal loads that arise as a result of sudden temperature changes.

Lightweight structures can experience high shear deformation which has to be modeled properly to accurately predict static and dynamic responses. This is done through nonlinear homogenization which allows effective finite element analysis. For this purpose we are developing high-order, non-linear, non-local beam and plate models.

For more information on FGMs, please click here

For more information on nonlinear homogenization, please click here

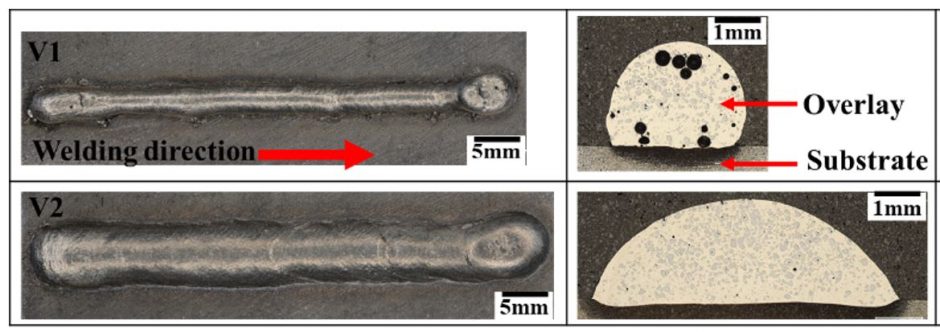

Welding, Fatigue and Structural Integrity

All-metal sandwich panels can be manufactured from thin plates. Such structures could severely decrease weight of engineering structures. To ensure high-quality, welding should cause minimal distortion and residual stress. Thus we are conducing research on low-heat input welding techniques using experimental and computational techniques.

For more information, please click here